In the challenging oceanic environment, reliable and resilient technology is essential to withstand harsh conditions and maintain optimal performance across a wide temperature range. Within the marine industry, hydraulic valve systems prioritize corrosion and explosion protection, emphasizing low leakage. Moreover, marine hydraulics encompasses specialized valves designed specifically for subaquatic applications. These valves can incorporate pressure compensation mechanisms to cater to underwater robots capable of diving to depths of up to 6,000 meters.

Motion of the Ocean

The advent of electro-hydraulic steering systems has revolutionized ship manoeuvring, offering enhanced precision and control. These systems combine hydraulic power with electronic controls, allowing seamless integration with advanced navigation and autopilot systems. Furthermore, joystick control systems have had a significant impact on ship manoeuvrability. With a single control interface, operators can effortlessly steer the vessel in any direction, making docking and close-quarters manoeuvring more efficient and safer.

Integrated Bridge Systems (IBS), used in conjunction with hydraulic steering interfaces, have become increasingly common, enabling centralized control and monitoring of various ship functions, including steering. This integration improves situational awareness and streamlines navigation operations.

Additional capabilities to assist in docking come from thruster-assisted steering systems utilizing hydraulic thrusters. These allow ships to move sideways and rotate without relying solely on rudder deflection. The rise in global trade, coupled with stagnation in port capacities, has made this feature particularly valuable for vessels operating in confined spaces or during delicate manoeuvres.

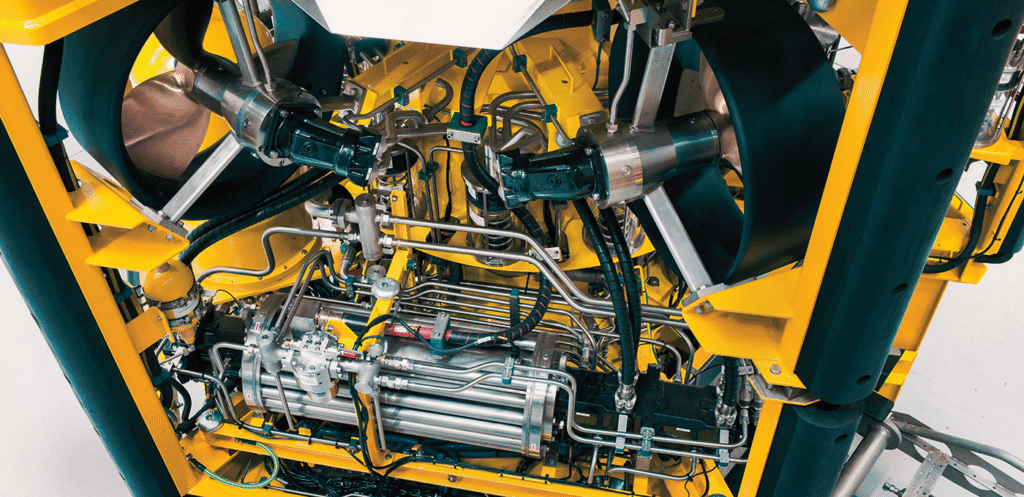

With hydraulic dynamic positioning, systems enable ships to maintain a precise position without anchoring. By using hydraulic thrusters and sophisticated control algorithms, ships can counteract external forces such as wind and current, ensuring station-keeping or slow-speed operations—such as offshore drilling or subsea construction.

Advanced control algorithms and sensor technologies have resulted in improved steering response and enhanced vessel stability. Integrated sensors provide real-time data on ship dynamics, allowing for optimal steering adjustments to counteract roll, pitch, and other motions—especially in larger cruise liners, where ensuring passenger comfort and safety is of prime importance.

Hydraulic systems equipped with redundancy and fail-safe features ensure reliable ship steering and manoeuvring, minimizing the risk of system failures and maintaining operational integrity in critical situations.

The integration of automation and artificial intelligence with hydraulic steering systems is enabling autonomous and remote-controlled ship operations. Ongoing R&D efforts are focused on further enhancing the efficiency and reliability of hydraulic steering and manoeuvring systems. Advancements in materials, sensors, and control technologies aim to optimize hydraulic performance, reduce energy consumption, and improve overall safety and manoeuvrability.

Remote Requirements

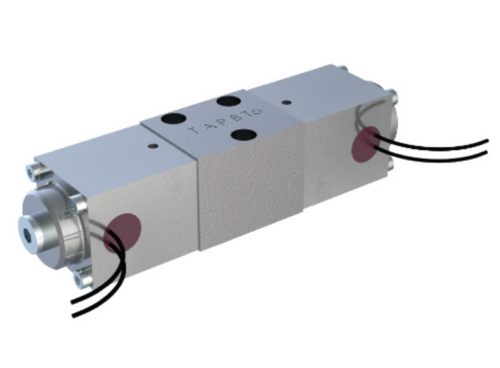

Proportional spool valves play a crucial role in controlling the precise motion of remotely operated vehicle (ROV) manipulators. These manipulators possess significant lifting capabilities, able to handle weights exceeding 500 pounds (225 kg) in air. However, alongside their power, the manipulators must also exhibit responsiveness and provide smooth, refined control to facilitate delicate adjustments of subsea equipment components.

Ensuring the effectiveness of ROV hydraulic components requires special modifications to withstand the rapid pressure changes experienced from sea level to the abyss, where ambient pressure can exceed 8,000 psi (600 bar). In the event of a system failure, the process of recovering and repairing an ROV is time-consuming—taking approximately eight hours to raise the vehicle to the surface vessel and then return it to a depth of 13,000 feet (4,000 meters). Consequently, Mean Time to Repair (MTTR) becomes highly critical in remote operating equipment due to the potential for extended downtime. Moreover, the cost incurred during periods of ROV downtime is exceptionally high, emphasizing the importance of efficient maintenance and swift repairs.

By leveraging hydraulic power, autonomous vessels can navigate and manoeuvre safely and efficiently, reducing the need for human intervention.

A Tale of Davits and Goliath

In our interconnected globalized society, the world’s largest ports handle container ships carrying massive volumes of cargo. To facilitate the loading and unloading process, these ports rely on advanced automated systems. Self-propelled lifting cranes (commonly referred to as straddle carriers) and gantry cranes (or Goliath cranes) efficiently stack containers in designated storage facilities within the port premises, often working with mere centimeters of tolerance.

Advancements in lifting and lowering operations using hydraulics have revolutionized cargo handling and vessel operations, offering increased efficiency, safety, and versatility.

Hydraulic-powered winches and lifting systems are also used in the installation and maintenance of offshore platforms and subsea equipment. The integration of sophisticated control systems with hydraulic lifting mechanisms enables precise positioning and synchronized movements, enhancing operational safety and reducing the risk of accidents.

These systems have enabled the development of innovative mechanisms such as hydraulic cranes, davits, and hoists, allowing for efficient lifting and lowering of heavy equipment to and from ships. For instance, modern cargo ships are equipped with hydraulic cranes capable of handling massive loads with precision, streamlining loading and unloading operations in ports worldwide. Similarly, hydraulic-powered davits are utilized for launching and recovering lifeboats, ensuring quick and safe deployment in emergency situations.

The hydraulic and electronic components integrated into lifting and lowering equipment operate continuously, around the clock. It is crucial to ensure their uninterrupted functionality, as any system failure can result in costly delays and financial implications.

Propulsion Power

Another focus area for marine hydraulics is propulsion systems. Many ships—particularly larger transoceanic vessels—utilize hydraulic systems in their propulsion mechanisms. Hydraulic transmissions and gear systems efficiently transfer power from engines to propellers, allowing ships to achieve high speeds while maintaining fuel efficiency.

Instrumental in maintaining stability and controlling vessel motion, especially in rough sea conditions, hydraulic valves also feature in stabilization and dynamic positioning systems. Hydraulic stabilizers and active fin systems counteract rolling motions, enhancing passenger comfort and reducing the risk of accidents. Additionally, dynamic positioning systems utilize hydraulic thrusters to maintain precise positioning without the need for anchors when the ships are landside.

The demand for hydraulic fluid media that possess specific properties—such as wear reduction, lubricity, suitable viscosity, environmental friendliness, and tolerance to water ingress—is crucial. However, developing environmentally friendly and fire-resistant hydraulic fluids presents significant challenges in meeting these requirements.

Some fluids with high water content pose difficulties, as standard valves are unsuitable due to concerns regarding lifespan, safety, reliability, and cost-effectiveness. Consequently, the need for subsea hydraulic systems to utilize environmentally friendly fluids has led to the development of new valves with specialized designs, materials, and construction techniques.

These valves incorporate internal components made of various grades and hardness levels of stainless steel to prevent galling and ensure compatibility with fire-resistant HFC and HFA fluids, as well as water-glycol-based fluids with water content up to 95%. Additionally, an optimized spool design has been implemented, offering increased resistance to internal cavitation caused by low-viscosity fluids at high pressure. This extends valve life and enhances the overall efficiency and effectiveness of the hydraulic system.

Advantage Hydraulics

Hydraulic systems offer substantial power and force with high power density, enabling the operation of heavy-duty marine equipment. Known for their durability and reliability in harsh environments—such as the salty, humid, and unforgiving maritime atmosphere—they provide robust performance even under the most challenging conditions. Stainless steel versions of valves offer additional protection, leading to longer life and reduced MTTR.

Hydraulic systems allow for precise control over movement and force, offering smooth and accurate operation. This level of control is crucial in maritime applications, where precision is essential for safety and efficiency. Marine hydraulic systems incorporate safety features such as pressure relief valves and overload protection, ensuring the protection of equipment, personnel, and the environment. These safety measures prevent excessive pressure build-up and minimize the risk of accidents.

Conclusion

Marine hydraulics play a pivotal role in ensuring reliable and efficient ship steering, manoeuvring, cargo handling, and propulsion systems. Hydraulic systems offer substantial power and force, making them ideal for heavy-duty marine equipment, while their durability and reliability make them well-suited for harsh maritime environments.

In the ever-evolving marine industry, ongoing research and development efforts aim to further enhance the efficiency, reliability, and safety of hydraulic systems. With their significant contributions to the marine sector, it’s clear that hydraulics continue to steer the course of progress in this challenging and dynamic domain.