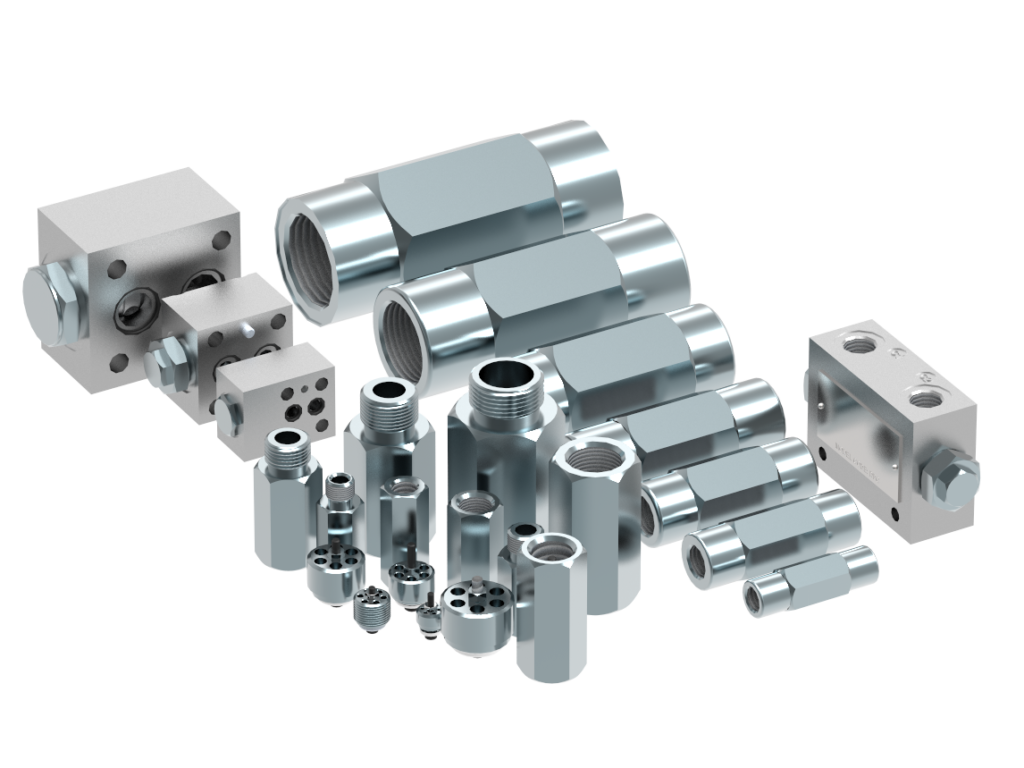

When it comes to controlling the flow of fluid in hydraulic systems, pilot check valves play a crucial role. These valves are designed to regulate the movement of fluid, prevent backflow, and ensure efficient operation of various hydraulic components. In this guide, we will delve into the world of pilot check valves, exploring their functionality, types, applications, and key considerations for optimal performance. Whether you’re a hydraulic system designer, engineer, or enthusiast, this article will provide valuable insights into pilot check valves and help you make informed decisions.

Tips for Selecting and Installing Pilot Check Valves: Identifying system requirements and specifications. Choosing the right valve size and type. Ensuring proper valve placement and orientation. Following manufacturer guidelines for installation. Testing and adjusting pilot check valves for optimal performance.

Identifying system requirements and specifications

Before selecting a pilot check valve, it is crucial to understand the specific requirements and specifications of your hydraulic system. Consider factors such as flow rate, pressure range, temperature conditions, fluid compatibility, and the application environment. Identify the purpose of the valve, whether it’s preventing backflow, controlling pressure, or maintaining system stability. By accurately assessing your system’s needs, you can choose a pilot check valve that matches your requirements.

Choosing the right valve size and type

Selecting the appropriate valve size is essential for optimal performance. An oversized valve may result in increased pressure drop and inefficient operation, while an undersized valve may restrict flow and cause system instability. Refer to flow charts and sizing guidelines provided by manufacturers to determine the correct valve size based on your system’s flow rate and pressure specifications. Additionally, consider the type of pilot check valve that suits your application. Direct-acting, pilot-to-open, pilot-to-close, pilot-operated, and combination pilot check valves each have unique features and are suitable for different scenarios. Evaluate the specific needs of your hydraulic system and choose the valve type that aligns with your requirements.

Ensuring proper valve placement and orientation

The placement and orientation of pilot check valves are critical for their efficient operation. Follow the manufacturer’s recommendations regarding valve placement in the hydraulic circuit. Improper placement can lead to issues such as pressure drop, increased turbulence, and potential damage to the valve. Ensure that the valve is installed in the correct direction of flow to prevent any backflow or pressure surges.

Following manufacturer guidelines for installation

Manufacturers provide detailed guidelines for the installation of pilot check valves. It is essential to carefully follow these instructions to ensure proper installation and avoid potential problems. Consider factors such as torque specifications for fasteners, appropriate sealing methods, and any additional components or fittings required for installation. Adhering to the manufacturer’s guidelines will help maintain the integrity of the valve and optimize its performance.

Testing and adjusting pilot check valves for optimal performance

Once the pilot check valve is installed, it is crucial to test and adjust it for optimal performance. Conduct a thorough system check to verify that the valve is functioning correctly. Use appropriate testing equipment, such as pressure gauges or flow meters, to measure and validate the valve’s performance under different operating conditions. If necessary, make adjustments to the valve’s pilot ratios or other settings to achieve the desired functionality and performance.

“Refer to flow charts and sizing guidelines provided by manufacturers to determine the correct valve size based on your system’s flow rate and pressure specifications. “

Regular maintenance and periodic inspections are also essential to ensure the continued optimal performance of pilot check valves. Follow the manufacturer’s recommended maintenance schedule and inspect the valve for any signs of wear, damage, or leakage. Proper maintenance and testing will help extend the lifespan of the valve and avoid unexpected system failures.

By considering these tips and following best practices, you can select and install pilot check valves effectively, ensuring reliable and efficient operation in your hydraulic system.